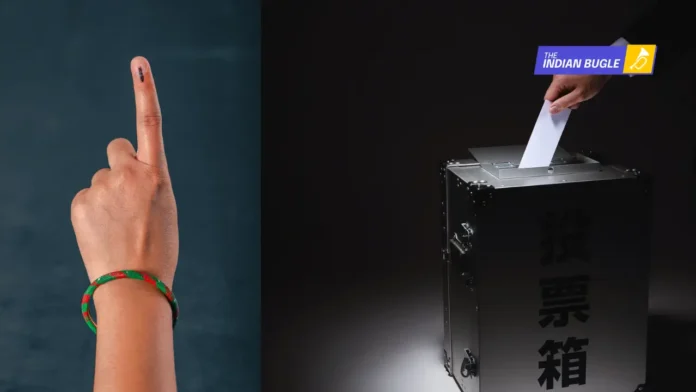

The purple mark on a voter’s finger might look simple, but it symbolizes one of the strongest pillars of democracy — free and fair elections. This mark, made using indelible ink, prevents multiple voting and ensures electoral integrity. Used in India and many other countries, this ink blends chemistry, innovation, and national trust.

The History of Voting Ink

Voting ink, also known as indelible ink or electoral ink, was first introduced in India during the early 1960s. It was developed by Indian scientists to stop fraudulent voting practices in large-scale elections. Since then, India has been a pioneer in using and exporting this unique ink to several countries worldwide.

The exclusive production rights are held by Mysore Paints & Varnish Ltd (MPVL), a government-owned company located in Mysuru, Karnataka. This company has supplied indelible ink for every election since its inception, serving not just India but more than 25 other democracies around the globe.

What Is Voting Ink Made Of?

The secret behind the ink’s long-lasting mark lies in its main ingredient — silver nitrate (AgNO₃), a light-sensitive chemical. When silver nitrate comes into contact with the skin and is exposed to sunlight, it reacts with proteins in the skin to create a dark stain that cannot be easily washed off.

Typical Composition of Indelible Ink:

- Silver nitrate (10–18%) – the key active ingredient that causes the stain.

- Dye or pigment – gives the ink its visible purple or violet color.

- Solvent (usually water-based) – helps dissolve and apply the solution easily.

- Thickening agents – control the flow and ensure proper adherence to the skin.

- Preservatives and stabilizers – prevent bacterial growth and maintain shelf life.

The formula ensures that once applied, the mark remains visible for days on the skin and several weeks on the nail.

How It Works

The process is pure chemistry in action. When the ink touches the skin or nail, silver nitrate reacts with keratin, a protein found in human tissues. Upon exposure to light, this reaction produces dark-colored silver particles, which form a semi-permanent stain.

That’s why polling officials apply the ink on the cuticle and nail, where it lasts the longest — often up to 2–4 weeks on nails and 3–7 days on skin. The mark naturally fades only as new skin or nail grows.

Where and How It Is Made

Voting ink in India is exclusively manufactured by Mysore Paints & Varnish Ltd, under the supervision of the Election Commission of India. The process is tightly secured to maintain confidentiality and ensure no duplication or misuse.

Production Process:

- Formulation: Silver nitrate and other ingredients are carefully blended in precise proportions.

- Testing: Each batch undergoes quality checks to confirm the right concentration and durability.

- Filling: The ink is packed in secure vials, brush bottles, or marker pens, depending on election requirements.

- Sealing and Packaging: Every unit is tamper-proof and coded for tracking.

- Distribution: The ink is sent to election commissions across India and to other countries that import it.

The factory in Mysuru increases production during election years, producing millions of vials to meet national demand.

Different Forms of Application

The ink is designed for quick and hygienic use during mass voting. Common applicators include:

- Small bottles with sponges — where the voter dips a finger.

- Marker pens — allow faster application and reduce cross-contamination.

- Brush bottles or sprays — used in some regions for convenience.

Regardless of format, the ink must dry instantly and resist washing, soap, or sanitizer for several days.

How Long Does the Ink Last?

The durability of the ink depends on where it’s applied and the concentration of silver nitrate:

- On skin: 3 to 7 days

- On nails/cuticles: 2 to 4 weeks (sometimes even longer)

It cannot be removed by washing or scrubbing. The stain fades naturally as the skin sheds and nails grow.

Safety and Health Aspects

Voting ink is safe for human use when handled properly. The concentration of silver nitrate is carefully controlled to avoid any adverse reactions.

Here are a few key safety points:

- It should not be applied to open wounds or broken skin.

- Minor irritation may occur for sensitive individuals, but it is extremely rare.

- Polling officers use protective gloves during the application.

- The ink is non-toxic and non-flammable.

Security and Anti-Counterfeit Measures

Because voting ink is an essential part of election integrity, its manufacturing and supply are tightly monitored. The formula and concentration are treated as confidential, and packaging includes batch codes, seals, and authentication features to prevent tampering or fake supplies.

Why Is It Used Only Once During an Election?

The entire purpose of indelible ink is to prevent double voting. Once the mark is made, it remains visible throughout the election period, ensuring that every citizen can vote only once. It’s one of the most cost-effective and foolproof security measures in large democracies.

Fascinating Facts About Voting Ink

- India first used voting ink in the 1962 general elections.

- Mysore Paints is the only licensed manufacturer in India.

- The ink has been exported to over 25 countries, including Thailand, Singapore, Malaysia, Nepal, and South Africa.

- The mark’s color and persistence may slightly vary depending on local light exposure and individual skin type.

- Once exposed to sunlight, the silver nitrate undergoes a photochemical reaction that darkens the mark over time.

Conclusion

A few drops of ink on a fingertip may seem small, but they play a massive role in upholding democracy. The indelible ink — born from Indian innovation and chemical precision — ensures that every vote counts once and only once.

It stands as a symbol of trust, participation, and the spirit of free elections, proving that sometimes, the smallest marks make the biggest difference.